Description

The Basic Purpose

◆ Paste label by the way of sucking-sticking, to achieve all kinds of plane labeling. Such as cosmetics flat bottles, packing boxes, labeling on the plastic cap and so on.

◆ Change the covering mechanism, make it suitable to the uneven surface’s labeling, such as concave flat, arc surface’s labeling and so on.

◆ Change the tool, make it applicable to a variety of irregular goods’ labeling.

◆ Optional ribbon coding machine and ink-jet printer, to print batch NO. and the production date on the label at the same time, to achieve a coding – Labeling’s integration.

Optional Features

Reader: Read 2D codes, bar codes and other information, establish products’ database for products’ traceability.

All-purpose Electric Eyes: General electric eyes cannot detect transparent labels, Leuze Electric Eye imported from Germany should be chose to be supportive.

Ink-jet printer: Can be equipped with the mainstream ink-jet printer in the market, print at specified location on the label, which can be combined with labeling machines perfectly.

Coder: Use thermal coder to print production date, expiration date, batch number and other information.

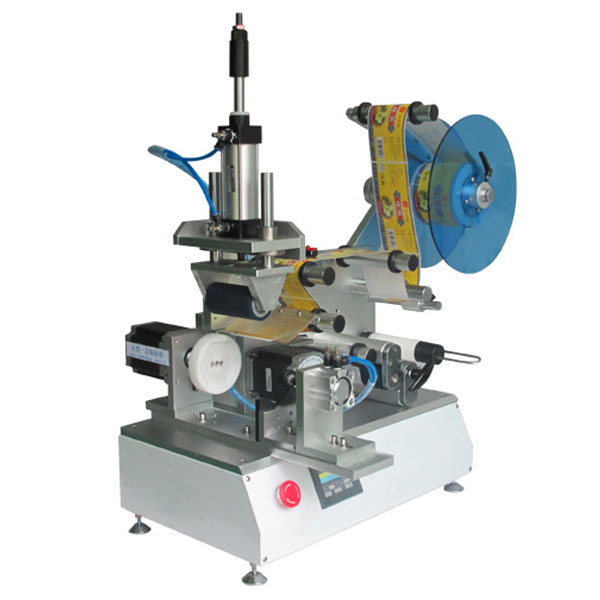

Whole View

| NO. | Mechanism’s Name | Mechanism’s Description |

| 1 | The Brake of Feed Tray | The prevention of over labeling |

| 2 | Feed Tray | Ready to put on label volumes |

| 3 | Rack | |

| 4 | Shrapnel to Press the Label | Press the label to ensure the label’s tension |

| 5 | Roller | For label’s detour |

| 6 | Label Detecting Electric-eye | Detect the label |

| 7 | The Material Receiving Machine | Recycle the label’s backing sheet |

| 8 | ‘T’Shape Handle | Fasten the drawing mechanism |

| 9 | Drawing Mechanism | By pulling the backing sheet, peel off the label, the degree of tightness can be adjusted |

| 10 | Electric Controlling Box | Used for the electric circuit configuration of the machine |

| 11 | Tool Table | Used to put on workpiece |

| 12 | Air Blowing Pipe | Hold up the label and transit it to the sucker successfully in the process of label peeling |

| 13 | Air Cylinder | Used to finish the action of labeling |

| 14 | Fine Adjustment Screw | Small adjustment for sucker and the height of workpiece |

| 15 | Film to Press the Label | Guarantee the tension of the label |

| 16 | Drawing Motor | Provide power to the label belt |

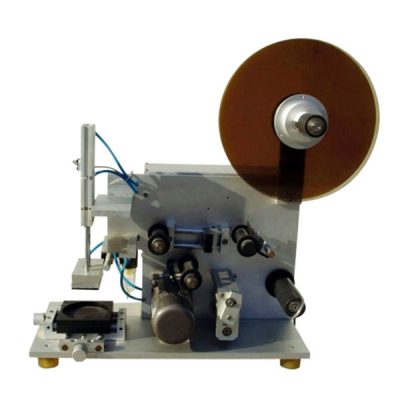

Rear view

1.Air Blowing Pipe 2.Pedal Interface 3.Standby Port 4. Standby Port 5.Air Pipe Interface 6.Barometer 7.Air Pressure Governor

Scope

◆ Applicable Label: adhesive label, adhesive film, electronic supervision code, bar code, etc.

◆ Applicable Products: The products required to be labeled on the plane, cambered surface , circumferential surface, concave surface, convex surface or other surfaces.

◆ Industry: Widely used in cosmetics, food, toys, daily chemical, electronics, pharmaceutical and other industries;

◆ Application: The labeling of shampoo flat bottles , packing box’s labeling, bottle caps, plastic shell, etc.

Technical Parameters

| Parameter Name | Specific Parameter Values |

| Labeling Accuracy | ± 0.5mm (except for products & labels’ error) |

| Labeling Speed | 15 to 25 pcs / min (related to products’ size) |

| Applicable Products’ Size | Length: 20mm ~ 200mm; Width: 20mm ~ 150mm;Thick:0.2mm~120mm |

| Applicable Label’s Size | Length: 15mm ~ 200mm; Width: 20mm ~ 200mm |

| Machine’s Size | Approximately 850mm × 410mm × 720mm (length × width × height) |

| Power supply | 220V/50HZ |

| Total Weight | Approximately 41Kg |

| Applicable label’s inner diameter | Ø76mm |

| Applicable label’s outer diameter | Ø 240mm |

| Voltage | 220V |

| Air Pressure | 0.4-0.6Mpa |

Working Process

◆ Core working principle :When the sensor detects the product or receives the signal sent from the pedal, the sucker which is sucking the label falls to label and covers the product, and then goes back to the original location to suck the next label and wait for the next label signal. The whole movements of the labeling have been finished.

◆ Procedure: Put the product -> Judge if product arrives (controlled by the detecting equipment or manually)-> Label and cover it(the device can achieve it automatically)->Remove the labeled products.

The following is the process of making label for a semi-automatic plane positioning machine.

(It can be sent directly to the label manufacturer for label production):

Note:

1.Distance between each two labels is 2-4mm

2.Use glassine paper

3.Inner diameter of label roll: 76mm, outer diameter: less than 260mm

Producing Requirements:

1. The distance between each two labels is 2-4mm;

2. The labels’ backing paper is made from glassine material, because this paper has good toughness in order to prevent being pulled apart

3. The inner diameter of label roll is 76mm, the outer diameter is less than 260mm, arranged in a single row.

The process of making label above should be combined with your products. The specific requirements please refer to the result of communication with our engineers!

Functional Features

◆ Powerful features, can be used for many kinds of workpiece labeling, such as plane, arc surface, concave plane and irregular workpiece.

◆Accurate when labeling, high stability, using PLC+ stepper motor drive to send label exactly; The feed tray that matched with brake function to make sure the tightness of the label belt, to ensure the accurate of label detection ; The label goes around the correction mechanism to prevent the label moving from left to right.

◆Strong and durable. Electric circuit and gas circuit are arranged separately. The gas circuit is matched with clean-up device to avoid the water in the air to damage the electrical equipment, lengthening its life; The whole machine is mainly made of stainless steel and high quality aluminium alloy.;

◆Convenient adjustment, it has a device which can adjust the height to fit different heights’ need and need not to change the tools frequently.

◆Beautiful shape. The bottom of the labeling machine is a electric box, equipped with stainless steel and high quality aluminium alloy, making it elegant and high-class;

◆Equipped with two ways to label: manual and automatic, worker can achieve labeling- control through sensor or pedal; Setting manual or automatic control button , and the length of the label can be controlled optionally.

◆Optional features and components: Thermal coding or ink jet, deliver products automatically, gather the products automatically(considered with products);special electric eye for labeling

Payment & Delivery

* MOQ: 1 Unit

* Port: Shanghai

* Payment Terms: T/T, L/C, D/A, D/P, Western Union, MoneyGram, Paypal

* Packaging Material: Paper/Wood

* Packaging Type: Cartons

* Delivery: We’ll arrange delivery within 3 days on the receipt of payment.

We Provide

* Best products and factory price.

* On-time delivery and the shortest delivery time.

* 1-year warranty. If our products cannot function properly within 12 months, we’ll offer spare parts for free; and you need to pay for the delivery.

* OEM and customized service.

* User manuals will go with relative machines.

Service

* QC: All products will be checked before delivery.

* Compensation: If any unqualified product is found, we’ll pay the compensation or send new qualified products to customers.

* Maintenance & Repair: In case of any maintenance or repair need, we’ll help to find out the problem and offer relative guidance.

* Operation Guidance: If you have any problem with operation, please feel free to contact us.

Reviews

There are no reviews yet.